***The following content was written by the author of the paper with URA.***

The power conversion efficiency of all-organic solar cells was doubled through the development of novel organic electrodes that can be fabricated using a moderate process.

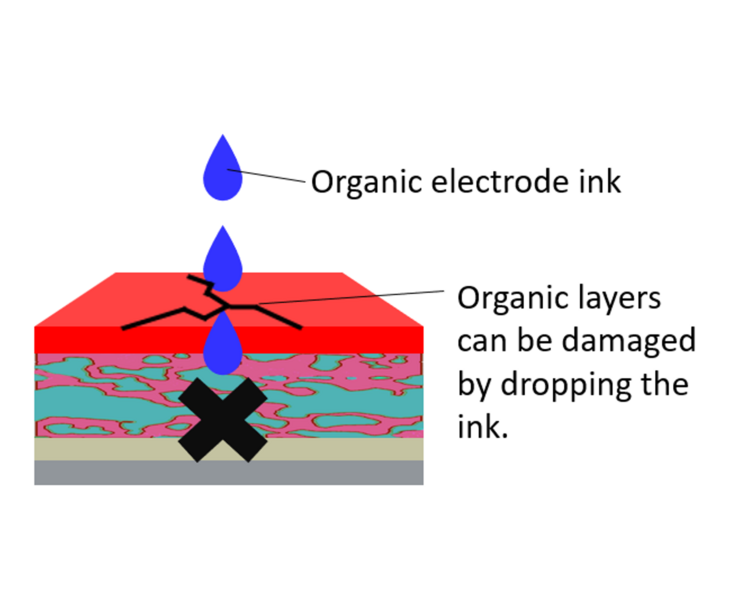

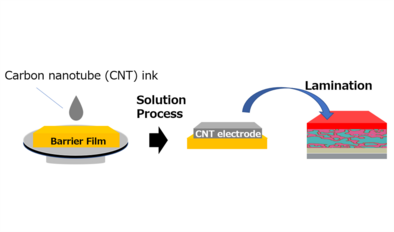

As global efforts to combat climate change continue, demand for solar energy is growing. However, since the currently most used silicon-based solar panels comprise a variety of hazardous substances, their disposal or recycling cause environmental impact and require substantial cost. The same issue is applicable to next-generation film-type solar cells, such as perovskite-based solar cells, as they also contain potentially hazardous materials such as lead compounds and metal oxides. To avoid such problems in disposal and reveal environmentally friendly energy source, scientists have sought film-type solar cells composed entirely of carbon-based materials (all-organic solar cells). Without hazardous metals they can be safely incinerated like regular plastics, which will significantly reduce environmental impact and disposal costs. Despite these advantages, the all-organic solar cells at present achieve very low power conversion efficiency (PCE), approximately 4% at most, which is far below those of conventional silicon solar cells (>27%) and perovskite solar cells (>26%). Thus, intensive technological advancements for high performance all-organic solar cells have been expected. Masahiro Nakano, Associate Professor from Institute of Science and Engineering, Faculty of Chemistry, Kanazawa University, has collaborated with scientists from REIKO Co., Ltd. (Junichi Iwai, President) and Queen's University at Kingston, Canada, and now successfully developed all-organic solar cells with the world’s highest efficiency. While the performance of previous all-organic solar cells was limited to about 4% PCE, the newly developed cells achieve more than twice efficiency than that of previous ones. Two major problems had previously hindered the performance of all-organic solar cells. First, the availability of highly conductive organic transparent electrode materials suitable for film-type solar cells is limited. Some high-conductivity organic materials had been reported, but their preparation required strong acids, bases, or high temperature annealing (>150°C), which could damage organic substrate films and organic semiconducting layers. To overcome this, the research team developed a transparent electrode based on conductive polymer PEDOT:PSS. The PEDOT:PSS-based electrode can be fabricated at a lower temperature (80°C) without using acids or bases, and it demonstrates sufficient conductivity (sheet resistance: <70 Ω/sq.) for film-type solar cells. The second problem is the difficulty in stacking multiple layers in the film-type solar cell device without damaging the underlying layers. In solution processes, the upper layer inks could make damages for the lower layers (Figure 1). To solve this problem, they developed "lamination method of carbon nanotube electrode (Figure 2)." This technique involves forming electrodes separately on the barrier films of solar cells and then attaching them to the device, avoiding damages to the bottom organic films during electrode fabrication. By combining the new organic transparent electrode and fabrication method, the research team successfully developed all-organic solar cells with more than twice the power conversion efficiency (8.7%) of previous models (4.0%). This advancement represents a crucial step toward the practical application of high-performance all-organic solar cells. Looking ahead, all-organic solar cells hold great promise for applications in environmentally sensitive areas, such as farmland and wearable devices. Their lightweight and flexible nature also allows for installation in locations where conventional solar panels would be impractical. The research team aims to further enhance performance by improving the conductivity of the organic electrodes.?

Figure 1

Figure 1

Figure 2

Click here to see the press release【Japanese only】

Journal: Advanced Functional Materials

Researcher's Information:Masahiro Nakano

PAGE TOP

PAGE TOP